Model:YTK-MPF4

This magnetic pump’s gear is made of 316 stainless steel, driven by permanent magnet and micro motor.

Suitable for Filling various liquid media, such as oil, water, syrup, cleaning agent, organic solvent.

YTK-MPF4 Magnetic Pump liquid filling machine

Description

This magnetic pump’s gear is made of 316 stainless steel, driven by permanent magnet and micro motor.

It features compact size, precision wise and low working noise.

Specification

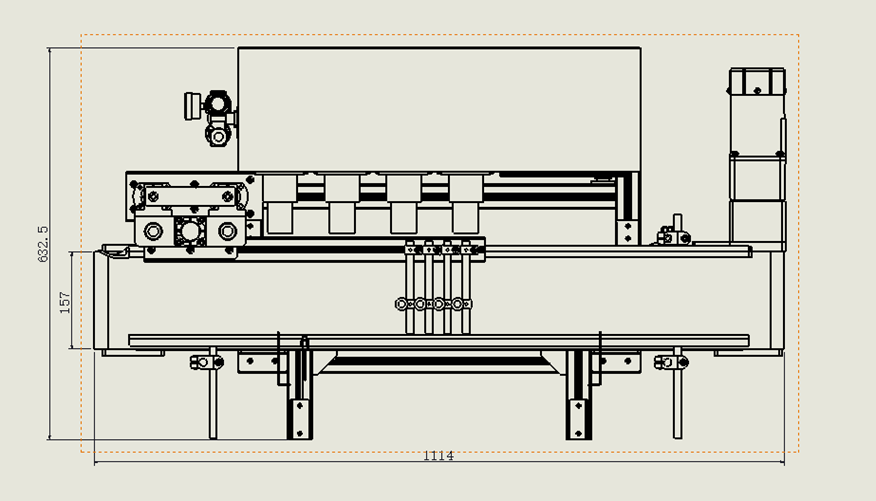

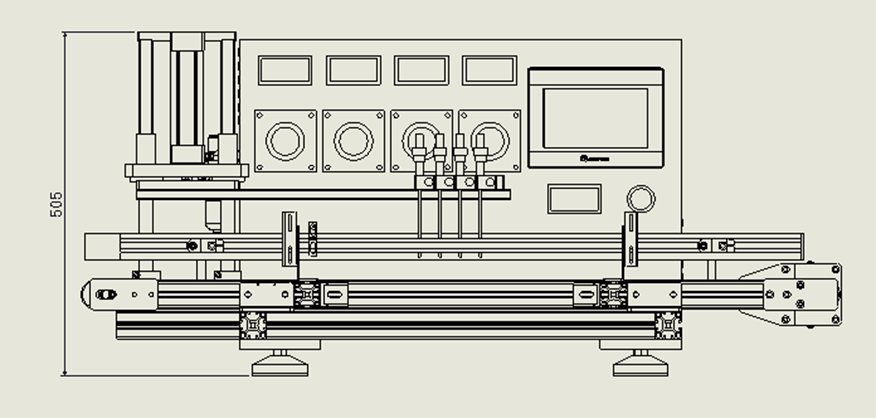

Machine Size | 1112*550*690mm |

Machine Weight | 50kg |

Package Size | 1142*590*720mm |

Package Volume Weight | 98kg |

Package Form | Wooden Case |

Minimum Bottle Diameter | 30mm |

Maximum Bottle Diameter | 125mm |

Minimum Bottle Height | 50mm |

Maximum Bottle Height | 200mm |

Nozzle Inner/Outer Diameter | 5/6mm |

Appliaction

This machine is suitable for filling various liquid media, such as oil, water, syrup, cleaning agent, organic solvent.

FAQ

The liquid spilling out of the bottle at the beginning of filling?

Please adjust the filling speed according to the height of your bottle, if your bottle is short, you can set the filling speed at a relatively low point to reduce the initial filling force to avoid spilling, and then you gradually increase the speed to try out which speed setting is best for you bottle.

How to set same filling volume for all 4 pumps?

1. Set same filling time and filling speed for fully fill all four bottles. For example, 10000ms(10s) and all 100 (max) speed. Test filling and observe the bottle, you’ll notice all 4 bottles has different liquid level.

2. Pick the pump that fills the lowest liquid level and we can use this as a guiding standard. Because this pump is weakest pump within all 4 , the only thing we need to do is lower the speed for the other 3 pumps to match this weakest pump.

3. Lower the speed setting for the other 3 pumps according to the liquid level you see and test filling again.

4. After some test fillings and speed adjustment, make sure the liquid level is the same within all 4 bottles by your naked eyes.

You stop here if you’re good with your result, but here are few more steps to make sure it’s even more accurate.

5. Get a electronic scale to weigh all four bottles.

6. Change the filling time, increase or decrease according to the weight you get from the scale, retry filling and you’ll make all 4 bottles has almost the same weight.

How to set the blocker, nozzle position?

We’ve showed this in our instruction, here’s a simple text version.

1. Fix a most left position you desire for the left blocker.

2. Place 4 bottles on the conveyor against the left blocker.

3. Move the sensor on the rail to aim at the first bottle.

4. Move the right blocker against the last bottle.

5. Move all the nozzles to match the mouth of your bottles.

6. Testing fill to check everything is all right.

Please scan this QR Code to see a working video of this machine

Or you can visit the link directly: https://youtu.be/yoLSWgn-9sE

Contact:

Phone:

E-mail: medpacking@126.com

Whatsapp:

Add: FL 3, BLD 1, Block 3(A), Xinhe Xinxing Industrial Park, Fuyong, Baoan, Shenzhen

We chat